Underground Mining Transportation

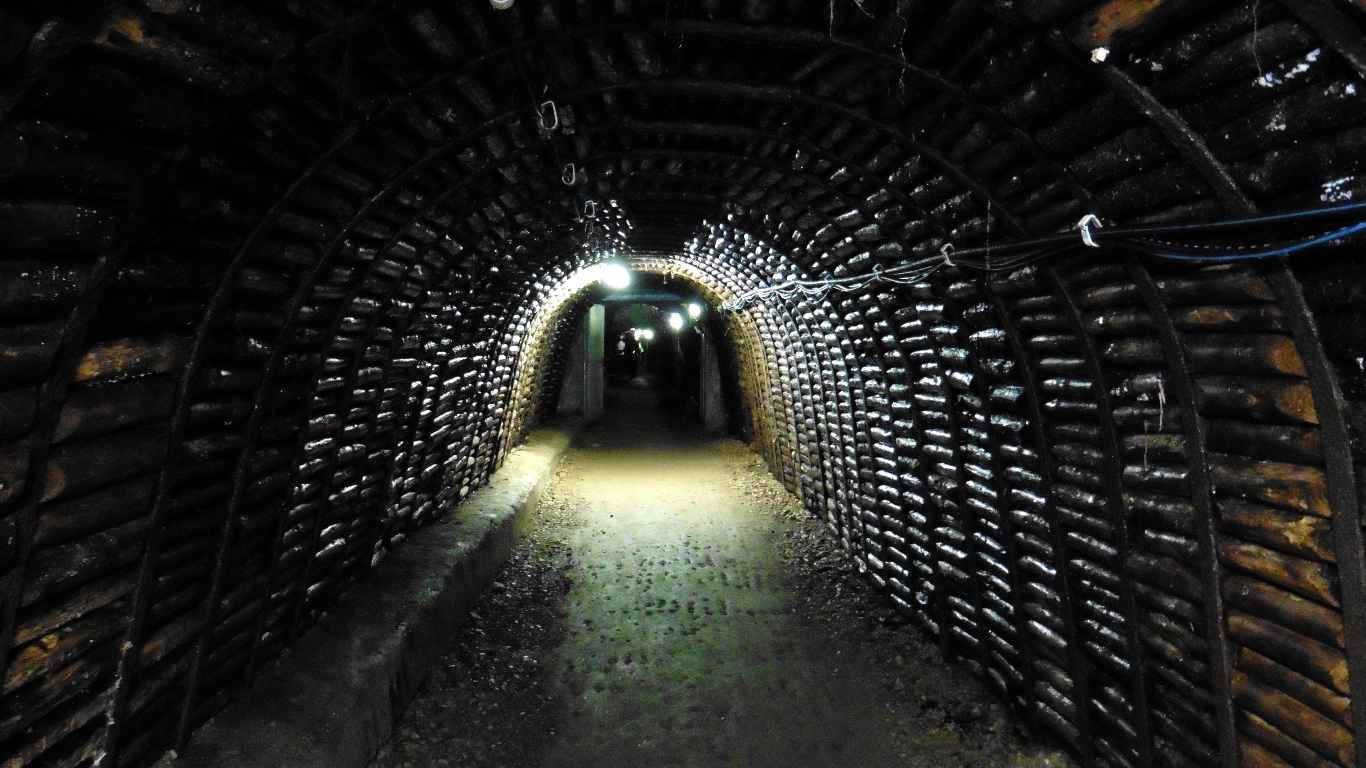

Underground mining transportation is significantly different from surface mining transportation, characterized by the unique challenges posed by narrow tunnels, limited spaces, and the need for robust safety protocols.

Overview of Underground Mine Truck Usage

Underground mine trucks are indispensable in subterranean mining operations, ensuring the efficient movement of ore and waste material through confined spaces. These vehicles are specially designed to navigate the often tight and winding underground routes, making them crucial for maintaining productivity and operational efficiency. Underground mine trucks must be agile, durable, and capable of handling the tough subterranean environment, enabling mining operations to continue smoothly and safely.

Types of Underground Mine Trucks

Two primary types of underground mine trucks are commonly used to optimize transportation tasks beneath the earth’s surface.

Load-Haul-Dump (LHD) Machines

Load-Haul-Dump (LHD) machines are versatile vehicles used for loading materials from the underground face, transporting them to the conveyor belts, or directly to the surface. LHDs are equipped with a front-mounted bucket, making it easy to scoop up material and transport it efficiently. These machines are critically acclaimed for their durability, ability to handle tough mining conditions, and effective mobility within narrow tunnels. The integration of LHDs into underground mining significantly reduces manual labor, enhancing both efficiency and safety.

Articulated Trucks

Articulated trucks are another key player in underground mining transportation. These vehicles feature a pivot joint that enhances their maneuverability, making them well-suited for the tight curves and restricted spaces of an underground mine. With a high load capacity and robust design, articulated trucks are essential for transporting large volumes of material swiftly and safely. Their flexibility and reliability help minimize operational downtime and contribute to the overall efficiency of underground mining operations.

Safety Measures for Underground Mine Trucks

Safety is paramount in underground mining transportation due to the inherent risks associated with operating heavy machinery in confined spaces. Various safety measures are implemented to mitigate these risks and ensure the well-being of mine workers. Firstly, strict maintenance protocols are enforced to keep trucks in optimal condition, preventing mechanical failures that could lead to accidents. Secondly, advanced training programs are provided to operators, emphasizing safe driving practices and emergency response procedures. Additionally, modern underground mine trucks are equipped with automated safety features such as collision detection systems, fire suppression mechanisms, and real-time monitoring, further enhancing operational safety.

Challenges and Solutions in Underground Mine Transport

Underground mining presents several challenges, including limited space, ventilation constraints, and the need for consistent material flow. Overcoming these obstacles requires innovative solutions. Enhanced ventilation systems are often implemented to ensure that exhaust emissions from trucks do not compromise air quality. Strategic route planning and the deployment of multiple trucks can help maintain a constant flow of materials, reducing the likelihood of bottlenecks. Furthermore, the application of cutting-edge technology, such as real-time tracking systems and predictive maintenance software, ensures that any potential issues are quickly identified and addressed, maintaining seamless underground transportation.

Innovations and Future Trends in Mining Transportation

The mining industry is continually exploring new technologies to optimize transportation efficiency and sustainability. Innovations in automated and electric vehicles, smart technology, and IoT integration are leading the way for the future of mining transportation.

Automated and Electric Vehicles

Automated vehicles are revolutionizing the mining transportation sector by reducing the need for human intervention and increasing operational efficiency. These vehicles can operate continuously and with precision, significantly reducing downtime and human error. Electric vehicles, on the other hand, are gaining traction as an environmentally friendly alternative to traditional fuel-powered machinery. By lowering emissions and reducing the dependency on fossil fuels, electric vehicles offer a sustainable solution for the future of mining transportation.

Smart Technology and IoT Integration

The integration of smart technology and the Internet of Things (IoT) is transforming mining transportation. IoT devices can monitor the performance of transportation equipment in real-time, providing valuable data that can be used to optimize operations and predict maintenance needs. This technology enables mine operators to make informed decisions, increasing efficiency and reducing the likelihood of equipment failure. Smart technology, including advanced software systems and automation, ensures that transportation logistics are managed seamlessly, contributing to safer and more productive mining environments.

Factors Affecting the Choice of Transportation in Mining

Selecting the most suitable transportation method in mining is influenced by several critical factors, including distance and terrain, the type of material being mined, and cost considerations.

Distance and Terrain

The distance between extraction sites and processing facilities is a significant factor in determining the best mode of transportation. For short distances, conveyor belts or LHD machines may be ideal. However, for longer distances, rail transport or articulated trucks might be more efficient. The terrain of the mining site also plays a crucial role; rugged or uneven terrain can necessitate the use of robust, all-terrain vehicles capable of navigating challenging landscapes.

Type of Material Being Mined

The characteristics of the mined material, such as its density, volume, and fragility, dictate the transportation method used. Heavier, bulkier materials may require the robust capabilities of dump trucks or rail systems, while more delicate materials might be better suited for transport via conveyor belts to minimize handling and reduce the risk of damage.

Cost Considerations

Cost is a pivotal consideration in the transportation decision-making process. Mining companies must evaluate the initial investment, operational costs, and maintenance expenses associated with various transportation methods. For instance, while automated and electric vehicles may have higher upfront costs, they can offer long-term savings through reduced fuel consumption and lower maintenance needs. Balancing cost with efficiency and sustainability is key to optimizing mining transportation strategies.

In addition, in order to ensure the safety and stability of Underground Mine Truck, we must choose a trustworthy brand.

Yantai Chi Hong Machinery Co., Ltd. offers a range of underground mine trucks that are designed to maximize tonnage and minimize extraction costs. The CHUK series of underground mine trucks are engineered with optimized machine width, length, and turning radius, enabling operation in narrow vein tunnels. These trucks are capable of carrying high payloads for their weight and are maneuverable and quick on inclines.

The CHUK-6/8 is one of the models in the CHUK series, with a capacity of 6 to 8 metric tons. It is equipped with features that enhance productivity and efficiency in underground mining operations. The truck is designed to operate fully loaded and at high speeds on long spiral haulage ways with gradients of up to 20%.

Another model in the CHUK series is the CHUK-12, which also offers features to maximize tonnage and minimize extraction costs. It has a capacity of 12 metric tons and is designed for operation in narrow vein tunnels. Similar to other CHUK trucks, it is built to operate fully loaded and at high speeds on long haulage ways with gradients of up to 20%.

For smaller and medium-sized hard rock mines, Yantai Chi Hong Machinery Co., Ltd. offers the CHUK-20 underground mine truck. Despite its relatively high payload capacity of 20 metric tons, this truck has the same overall width as most 15-ton trucks on the market. It is designed to operate fully loaded and at high speeds on long spiral haulage ways with gradients of up to 20%.

All of Yantai Chi Hong Machinery Co., Ltd.’s underground mine trucks are designed with durability and performance in mind. They are equipped with advanced powertrain technology, including proven transmissions with automatic gear shifting and torque converter lock-up, ensuring fast ramp speeds and efficient tunnel clearing. The trucks also feature durable axles with limited slip differentials for traction and spring-applied hydraulic release brakes for safer braking.

In summary, Yantai Chi Hong Machinery Co., Ltd.‘s underground mine trucks are reliable and efficient solutions for underground mining operations. With their optimized design and advanced features, these trucks offer high productivity and cost-effectiveness in narrow vein tunnels.

In conclusion, the efficient transportation of materials is a cornerstone of successful mining operations. Whether it involves heavy machinery in surface mining or specialized vehicles in underground mining, each mode offers unique advantages tailored to the specific challenges of the mining environment. With ongoing advancements in technology and a growing emphasis on sustainability, the future of mining transportation looks set to become increasingly efficient and environmentally friendly.