Understanding the Key Factors in Underground Mining Trucks

The Importance of Payload Capacity in Mining Operations

Payload capacity is a big deal for mining trucks. It sets how much stuff you can haul at once. This affects how much work gets done. In underground mines, you move tons of ore or waste through tight spaces. Trucks with bigger payloads cut down on trips. That saves time and fuel. It also boosts profits.

The Role of Maneuverability in Narrow Tunnels and Steep Grades

Maneuverability is just as key. Underground mines are cramped. Trucks need to zip through sharp turns and steep slopes. A tight turning radius helps a lot. So do bendy designs. Take the CHUK-6/8 Mine Truck from Yantai Chi Hong Machinery Co., Ltd. It’s built small with great turning skills. It handles tough spots like a champ.

Balancing Efficiency and Productivity in Underground Mining

You’ve got to juggle efficiency and output. Big payloads mean fewer trips. But good maneuvering keeps things moving in tight spots. A truck that nails both is gold. It keeps work smooth and steady.

Evaluating Payload Capacity in Underground Mining Trucks

How Payload Capacity Impacts Haulage Efficiency

Payload capacity drives how well hauling goes. Bigger loads mean fewer runs. That cuts fuel use and wear on gear. It lowers worker costs too. But overloading is bad news. It can break trucks or cause accidents. Pick a truck that fits your mine’s needs just right.

Comparing Payload Capacities of Common Underground Mining Trucks

Trucks come with different load sizes for different jobs. Here’s a look at some:

WJ-0.6 Loader: Holds 0.6m³. Weighs 4,800kg. Great for small gigs.

WJ-1H Loader: Carries 2 metric tons. Has smart diagnostic tools for easy fixes.

WJ-2 Loader: Built for mid-size tasks. Hauls 4 metric tons.

UK-6 Mine Truck: Tough for bigger jobs. Takes up to 6 metric tons.

Each is made to boost work while staying safe and solid.

When to Prioritize High Payload Capacity

Go big on payload for huge mines. If you’re moving lots of stuff far, it’s a win. Fewer trips save cash. But make sure the truck fits your tunnels. Big loads in tight spaces can spell trouble.

The Significance of Maneuverability in Underground Mining Trucks

Maneuverability Features for Navigating Tight Spaces

Trucks for mines have slick features. Think slim builds and short lengths. Smart steering helps too. The CHUK-15 Mine Truck is a good example. It’s compact but still hauls heavy. It weaves through narrow veins like a breeze.

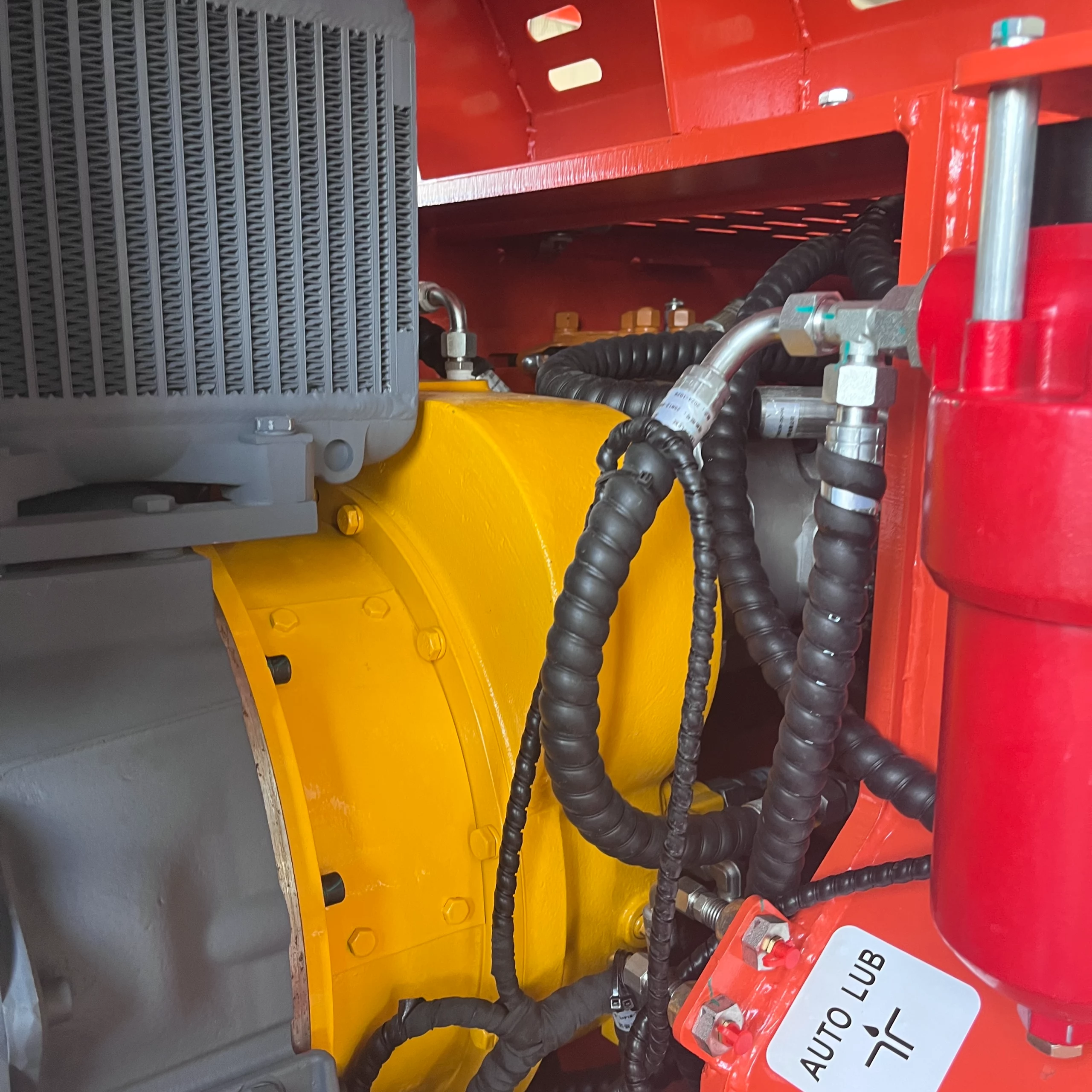

The Impact of Articulated Design on Truck Maneuverability

Bendy designs make trucks nimble. The front and back move on their own. This helps with sharp corners and bumpy ground. The CHUK-12 is a pro at this. It stays steady while twisting through tough paths.

Scenarios Where Maneuverability is Crucial

Maneuverability shines in tricky spots. Here’s where it counts:

Narrow Veins: The CHUK-6/8 is a star. Its small size fits tight spots.

Steep Slopes: Strong engines keep things smooth. They handle grades up to 20%.

Emergencies: Fast moves can save lives. Quick exits or clears are key.

Comparing Payload Capacity and Maneuverability Across Models

Analysis of AD22, AD30, AD45, and AD63 Truck Models

Trucks like the AD22, AD30, AD45, and AD63 show how payload and maneuvering matter. Each fits different jobs. The AD22 is small and quick. It’s perfect for narrow veins. The AD63 is a beast for big hauls. It’s made for large mines.

The AD30 hits a sweet spot. It carries a decent load and moves well. The AD45 pairs nimble handling with solid capacity. It’s great for mid-size mines with tight spots. Knowing these differences helps pick the right one.

Power-to-Weight Ratios and Their Influence on Performance

Power-to-weight ratios are huge. They affect speed and climbing power. A good ratio means better hauling under load. The CHUK-6/8 Mine Truck nails this. It’s small but strong. It zips through tunnels with ease.

Bigger trucks like the CHUK-12 focus on heavy loads. They still use clever designs to stay efficient. This balance is key on steep 20% grades. It keeps trucks running without breaking down.

Technology Enhancements Supporting Both Payload and Mobility

New tech makes trucks better at both hauling and moving. Smart steering and control systems are game-changers. Real-time diagnostics catch issues fast. The WJ-1H Loader has this down. It tracks everything to keep work smooth.

Bendy designs add flex too. They let trucks twist through rough spots. This cuts wear over time. Trucks with these perks run better and last longer.

Choosing the Right Underground Mining Truck for Your Needs

Assessing Operational Requirements and Site Conditions

Picking a truck starts with knowing your site. Check tunnel size and slope steepness. Think about what you’re hauling and how far. For small jobs or tight paths, the WJ-0.6 Loader is spot-on. It’s narrow with a tight turn radius.

Mid-size mines need balance. The WJ-2 Loader hauls 4 metric tons and moves well. Big sites want power. The UK-6 Mine Truck handles 6 metric tons like a pro.

Finding the Balance Between Capacity and Flexibility

You need the right mix of load size and agility. Big payloads cut trips. But they can jam up in small spaces. Nimble trucks shine in tight spots. They might need more runs, though.

The CHUK-15 Mine Truck blends both. It’s compact yet hauls a lot. It fits narrow veins without slowing down. Match your truck to your mine’s needs for the best results.

Long-Term Benefits of an Optimized Truck Selection Strategy

Choosing the right truck pays off big. It cuts repair costs. Less stress on gear means fewer fixes. It keeps workers safe too. Stable trucks handle tough spots better.

Smart systems save time. Quick diagnostics mean less downtime. Yantai Chi Hong Machinery Co., Ltd. offers custom fits. They tweak trucks to match your project. This saves money and boosts work across all mine sizes.

A smart pick based on your site and goals keeps costs low. It helps your mine grow strong and stay ahead.

Frequently Asked Questions

What factors should I consider when choosing an underground mining truck?

Look at tunnel size and slopes. Check material type and haul distance. Payload needs and maneuvering features matter too.

Why is power-to-weight ratio important in underground trucks?

It sets how fast trucks speed up. It helps them climb steep slopes. It keeps performance solid under heavy loads.

What are some examples of compact yet high-performing underground trucks?

The CHUK-6/8 Mine Truck is a great pick. It’s small but packs strong payload power for tight mines.

How does Yantai Chi Hong Machinery Co., Ltd.‘s customization service benefit operators?

They tailor trucks to your needs. This boosts work flow and cuts costs.