Understanding Dump Truck Mining

Definition and Importance

Dump truck mining plays a crucial role in resource extraction, essential for transporting large quantities of mined materials. These trucks are specifically designed to manage heavy and bulky loads, making them vital to mining operations. They improve efficiency by swiftly moving soil, minerals, and rocks, thereby cutting down the time and labor associated with traditional transport methods. By enabling fast and substantial movement, dump truck mining enhances the productivity of mining sites and significantly boosts the overall output of the mining industry.

History and Evolution of Dump Trucks in Mining

The history of dump trucks in mining dates back to the early 20th century when rudimentary versions were first employed. Over the decades, these vehicles have evolved from small, manually operated machines to sophisticated, highly automated systems. The development of dump truck mining has been marked by technological advancements, from steam-powered tipper wagons to diesel-powered behemoths capable of hauling hundreds of tons. The continuous evolution has resulted in enhanced load capacities, improved durability, and safer operational standards, reflecting the industry’s growing demands and technological strides.

Types of Dump Trucks Used in Mining

Off-Highway Dump Trucks

Off-highway dump trucks are specifically designed for mining and heavy-duty construction tasks. These massive vehicles operate efficiently on rugged terrain and are often used in large-scale mining operations. They boast impressive load capacities, transporting substantial amounts of materials in a single trip. Off-highway dump trucks are built to withstand harsh environmental conditions, making them indispensable for transporting extracted resources from mining sites to processing locations.

Articulated Dump Trucks

Articulated dump trucks are versatile and flexible, characterized by their unique articulated frame that enhances maneuverability. These trucks are particularly useful in mining sites with uneven terrain and tight spaces. They combine high load capacity with superior agility, making them ideal for operations that require frequent changes in direction and navigation through challenging landscapes. Their articulated joints allow for better weight distribution and improved stability, essential for carrying heavy loads safely.

Rigid Frame Dump Trucks

Rigid frame dump trucks, also referred to as fixed-frame trucks, are renowned for their strength and substantial payload capacities. Unlike articulated dump trucks, these vehicles have a non-articulated structure, resulting in a more straightforward and stable frame. These trucks are ideally suited for mining environments with well-maintained haul roads where maximizing load capacity is essential. Rigid frame dump trucks are notable for their durability and efficiency, ensuring the consistent and reliable transportation of extracted materials in large-scale mining operations.

Essential Features of Dump Trucks for Mining

Load Capacity and Efficiency

Load capacity is a critical feature of dump truck mining. The ability to carry large loads efficiently can drastically reduce the number of trips needed, cutting down overall operation time and costs. Modern dump trucks are engineered to maximize payload without compromising safety and performance. This efficiency in load management directly translates to improved productivity and profitability for mining operations.

Durability and Reliability

Durability and reliability are non-negotiable traits for mining dump trucks. These vehicles operate in extreme conditions, from abrasive materials to highly rugged terrains. High durability ensures that the trucks can withstand regular wear and tear over time, while reliability minimizes downtime due to maintenance and repairs. By maintaining operational consistency, dump trucks enhance the overall efficiency of mining projects.

Advanced Technology Integration

The integration of advanced technology has revolutionized dump truck mining. Modern dump trucks are equipped with GPS tracking, on-board diagnostics, and automated systems that enhance performance and safety. These technological features enable real-time monitoring, route optimization, and predictive maintenance, all contributing to the smoother operation of mining activities. Technology integration not only improves efficiency but also helps in adhering to stringent safety and environmental standards.

Environmental Impact of Dump Truck Mining

Emissions and Pollution Concerns

The environmental impact of dump truck mining is a significant concern, with emissions and pollution from diesel engines contributing to air quality deterioration. Mining operations often involve extensive use of these trucks, leading to substantial greenhouse gas emissions. Noise pollution is another issue, as the extensive use of heavy machinery disturbs the local environment. Addressing these concerns is crucial for minimizing the ecological footprint of mining activities.

Mitigation Strategies

To mitigate the environmental impact, several strategies are being employed within the industry. The adoption of electric and hybrid dump trucks is gaining traction, aimed at reducing carbon emissions and improving fuel efficiency. Regular maintenance and the use of cleaner fuels can also significantly lower pollutants. Additionally, implementing stricter emission regulations and investing in green technologies are vital steps toward more sustainable dump truck mining practices. These measures not only protect the environment but also pave the way for a more responsible and eco-friendly approach to resource extraction.

Safety Measures in Dump Truck Mining Operations

Operator Training and Certification

Operator training and certification play a crucial role in ensuring the safety of dump truck mining operations. Comprehensive training programs are designed to educate operators on the proper use and maintenance of the equipment, which is vital for preventing accidents and injuries. Certification ensures that operators meet the necessary standards and are competent in handling the complexities of mining dump trucks. Regular refresher courses and continuous education are essential to keep operators updated with the latest safety practices and technological advancements in the field.

Equipment Safety Features

To enhance the safety of dump truck mining, modern dump trucks are equipped with a range of safety features. These include advanced braking systems, collision avoidance technology, and reinforced cabs to protect operators in case of accidents. Additionally, visibility aids such as cameras and radar systems help operators navigate difficult terrains and avoid obstacles. These safety features are designed to prevent accidents and reduce the risk of injury, ensuring a safer working environment for all personnel involved in mining operations.

Site Safety Protocols

Effective safety protocols are crucial in minimizing risks associated with dump truck operations in mining environments. These measures include strict compliance with speed regulations, routine maintenance inspections, and the mandatory use of personal protective equipment (PPE) by all workers. Establishing clear communication channels and having well-defined emergency response plans are essential for managing unexpected incidents quickly and effectively. By enforcing and following stringent safety guidelines, mining sites can considerably lower the chances of accidents, thereby enhancing overall worker safety.

The Economic Significance of Dump Truck Mining

Cost-Benefit Analysis

The economic significance of dump truck mining lies in its ability to optimize costs and benefits in mining operations. A thorough cost-benefit analysis reveals that, despite the high initial investment in dump trucks and associated technology, the long-term gains in efficiency and productivity outweigh the costs. These trucks reduce the need for multiple trips, lower fuel consumption, and minimize labor costs. Additionally, the enhanced durability and reliability of modern dump trucks lead to reduced maintenance expenses and downtime, further contributing to the economic viability of mining projects.

Impact on Employment

Dump truck mining has a substantial impact on employment within the mining industry. The operation and maintenance of these trucks require a skilled workforce, providing job opportunities for equipment operators, mechanics, and safety inspectors. The growth and technological advancements in the industry also spur the need for ongoing training and education, leading to the creation of more specialized roles. Consequently, dump truck mining not only contributes to the economic growth of the mining sector but also supports local economies by creating and sustaining numerous jobs.

Innovations in Dump Truck Mining Technology

Autonomous Dump Trucks

The advent of autonomous dump trucks represents a significant innovation in dump truck mining technology. These self-driving vehicles are equipped with advanced sensors, GPS, and artificial intelligence to navigate mining sites without human intervention. Autonomous dump trucks enhance operational efficiency by reducing human error, improving safety, and allowing for continuous operation without breaks. This technology also optimizes resource allocation and can be particularly beneficial in hazardous environments where human presence poses additional risks.

Fuel Efficiency Improvements

Enhancing fuel efficiency is a primary focus in the development of dump truck mining technology. Contemporary dump trucks incorporate sophisticated engine technologies and aerodynamic designs aimed at lowering fuel usage and emissions. The adoption of hybrid and electric powertrains is becoming increasingly popular, offering a more eco-friendly alternative to conventional diesel engines. These innovations not only cut operational expenses but also help to mitigate the environmental impact of mining operations by reducing greenhouse gas emissions.

Real-Time Monitoring Systems

Real-time monitoring systems have revolutionized dump truck mining operations by providing continuous data on various aspects of the trucks’ performance and the mining environment. These systems include on-board diagnostics, GPS tracking, and remote monitoring capabilities that allow for real-time analysis and decision-making. Operators and managers can track fuel usage, engine performance, load weights, and route efficiency, enabling them to optimize operations and address potential issues before they escalate. Real-time monitoring enhances operational efficiency, ensures compliance with safety standards, and promotes proactive maintenance strategies.

By integrating these innovations and maintaining rigorous safety measures, dump truck mining continues to play a critical role in the sustainable and efficient extraction of resources, supporting both economic growth and environmental stewardship.

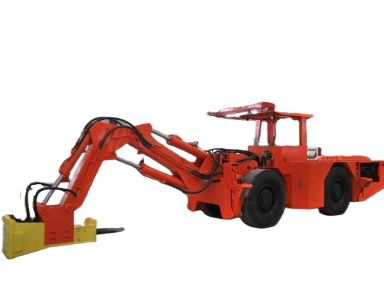

Yantai Chi Hong Machinery Co., Ltd. is a leading supplier in China’s mine machine manufacturing industry, specializing in the production of dump trucks for underground mining. Their dump trucks are designed to operate fully loaded and at high speeds on long spiral haulage ways with up to 20% gradients.

The CHUK-6/8 dump truck is one of their featured products, designed to help mines maximize tonnes and minimize extraction costs. It has been engineered to optimize machine width, length, and turning radius, enabling operation in narrow vein tunnels.

Another model is the CHUK-12, which also focuses on maximizing tonnes and minimizing extraction costs. It shares similar features with the CHUK-6/8, such as optimized machine dimensions for narrow vein tunnels.

For small and medium-sized hard rock mines, Yantai Chi Hong Machinery Co., Ltd. offers the CHUK-20 dump truck. Despite its relatively high payload capacity of 20 metric tons, it has the same overall width as most 15-ton trucks on the market.

Overall, Yantai Chi Hong Machinery Co., Ltd. provides a range of dump trucks specifically designed for underground mining, offering high performance, maneuverability, and efficiency in various mining conditions.